Building Products

Your Globe Team

Mike Tart

Sales Manager

Building Products

253.229.0142

miket@globemachine.com

Jeff Johnson

Director

Strategic Business & Sales Development

678.231.8847

jeffj@globemachine.com

Vision Statement

Globe Machine’s heritage of wood-based building product solutions spans more than 100 years. Today, we continue our legacy while constantly developing the next generation of products and systems. The Globe Machine Building Products business unit is an industry leader you can rely on for decades to come.

Why Choose Globe for your Building Products Solution?

MADE IN

THE U.S.A.

HIGH QUALITY

MATERIALS

FACTORY AUTOMATION

EXPERTS

CUSTOM ENGINEERED

SOLUTIONS

24/7 Support

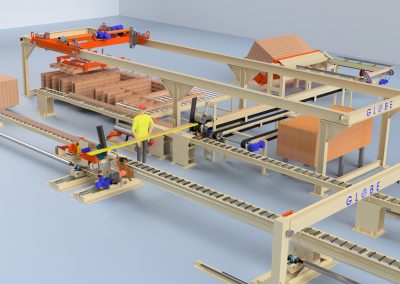

Building Product Solutions

OSB Manufacturing Systems

OSB & OSL finishing lines encompass all the processing equipment located after the press unloading phase of production. We design and manufacture custom systems with applications in cooling, sawing, grading, stacking, sanding, edge profiling, edge sealing, conditioning, packaging, and foil application. Our engineering process allows our customers a complete array of choices not only in configuration but also in machinery. Globe has built finishing equipment for a majority of North America’s OSB plants, and supplies equipment for plants around the world.

MDF & Particleboard Manufacturing Systems

Globe Machine finishing lines for MDF and particleboard plants are designed to produce quality products while adapting to growing industry requirements and capacity. Our customer-tailored systems take raw boards from the press and process them through any needed means: cooling, storage, sanding, sawing, and packaging with efficiency and reliability. Globe’s industry reputation is well known, with our latest solutions busy cutting thin boards from continuous presses in some of the world’s newest MDF plants.

Plywood Manufacturing Systems

The continuous improvement of plywood machinery has been at the core of our business since our inception. Our machines are capable of processing material from the dryer outfeed through to the finished products. Globe Machine trim saws, specialty saws, pre-presses, and glue spreaders are just a few examples of staple machinery we have been supplying to industry leaders for decades. Our machines are made with toughness and efficiency in mind, allowing plants to rely on their Globe custom systems to produce quality products for decades to come.

I-joist, LVL, and OSL Manufacturing Systems

As an engineered wood product, wood I-joists offer technical advantages over their traditional counterparts. They are generally more consistent in straightness and stability and have a greater span rating. Globe Machine fabricates a complete equipment package for the manufacture of wood I-joists. Our patented I-joist Assembly is completely controlled by a central computer, allowing unique parameters for different-sized beams and individual setups without the need for manual readjustment.

Panel and Lap siding Manufacturing Systems

Globe’s largest and highest-performing press; 12,000 – ton capability, 10 – opening, vacuum enclosed, with 5’x10’ heated platens, has been operational in a production composite armor factory for more than 12 years. It is automatically loaded and unloaded by a 10 – position Globe press-loader system. Let us review your application to determine how one of our ultra-high-pressure press lines could improve your manufacturing environment and expand your product line.

Moulded Doorskin Manufacturing Systems

Originally serviced by our affiliate, Burelbach Industries, the challenges with handling and processing of MDF moulded door skins after exiting the press are now met and perfected by Globe. We offer special alignment and sawing equipment custom – designed to fit your factory needs. In addition to trimming, stacking, feeding, and cooling, we manufacture complete paint line systems. Panels are conveyed thro ugh continuous coating lines and heated ovens to accurately apply and cure primer coats.

Fiber Cement Manufacturing Systems

Globe manufactures fiber cement finishing and coating systems for sheet, plank, and trim products. Our solutions are tailored to the customer’s specific products and capacity requirements. Designs are built upon decades of experience supplying the wood-based panel and engineered wood products industries, and represent a unique product line that is customized for the needs of the fiber cement market.