Custom Solutions

Your Globe Team

Vision Statement

As a US-based world leader in automated factory systems for building product producers, Globe Machine offers our expertise gained over more than a century for your Custom Manufacturing requirements. We develop engineered solutions using advanced technologies, in-house designed custom equipment, and factory automation specific to your project.

Why Choose Globe for your Custom Solutions?

MADE IN

THE U.S.A.

HIGH QUALITY

MATERIALS

FACTORY AUTOMATION

EXPERTS

CUSTOM ENGINEERED

SOLUTIONS

24/7 Support

Custom Solutions

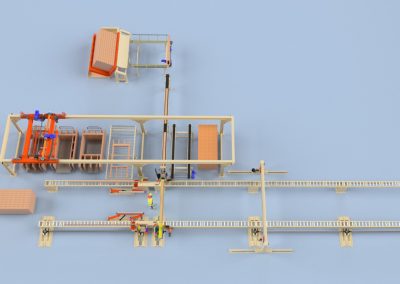

You bring ideas or designs, and we bring engineering and manufacturing expertise. Want to increase production goals? Are you facing unique factory challenges? Globe helps you accomplish your goals and add value to your project. Here are some of our previous Custom Manufacturing solutions and capabilities. Contact us for more information and to share your specific factory needs.

Custom Presses

Globe Machine is experienced in taking detailed requirements for products and creating corresponding systems from the ground up. For example, by leveraging decades of experience designing and manufacturing presses for the wood products industries, we engineered and manufactured a 12,000-ton press to solve a customer’s production challenges.

Custom Lifts

We proudly manufacture a full line-up of custom hydraulic and electric scissor lifts. These designs are incorporated in many of our systems for Building Products and Pulp & Paper, but frequently, our scissor lift solutions take on a life of their own as specialized projects for Custom Manufacturing Customers. These are Mobile Jet Engine Maintenance and Jet Engine Cell Testing Lifts. Below them are smaller lifts incorporated into automated systems.

Aerospace Automation

This specialized machine serves as an example of our ability to replace an old mechanical-based process with a non-mechanical solution that increases efficiency and uptime while eliminating operator interaction that had previously put operators in harm’s way. Just like seen here, all of our solutions are put through numerous factory acceptance tests to assure proper functionality and to give customers insight into manufacturing progress.

Engineering

Globe Machine’s in-house engineering team tackles challenging projects by developing factory solutions from the ground up. We constantly adapt and build upon the success of our knowledge to meet the rigors of our customer’s needs. Our staff consists of mechanical and electrical engineers, PLC and robotics programmers, system engineers, project managers, enterprise resource planning specialists, technical writers, and lab technicians. No matter what your project requires, our team of engineers is ready to create innovative solutions.

Fabrication

Our fabrication shop is part of our 140,000-square-foot manufacturing facility. Our custom-installed overhead cranes support jobs of any scale, while plasma cutters 12’ sheer, 12’ press break, saws, and multiple welding stations ensure we are capable to develop systems tailored to your requirements.

Machine Shop

Critical to our manufacturing operation, Globe’s facility includes a 40,000 – square-foot machine shop equipped with CNC and conventional machines. This means the production of equipment will not be delayed due to machining needs. Our machine shop is also home to our fiercely detailed inspection department, where we ensure critical components are consistent with requirements and standards.

Mechanical and Electrical Assembly

Our facility includes 100,000 square feet dedicated to fabrication, assembly, painting, and testing, and includes a complete electrical panel and hydraulics shop. Our experienced and diverse assembly teams perform every aspect of the manufacturing process for our Custom Manufacturing projects including mechanical, electrical, hydraulic, and pneumatic assembly. Our teams are led by managers with decades of experience in manufacturing and assure precision and expertise with the construction of your solutions.